Author: Mariela Guanchez

Ever wondered how solar panels are made—and why that matters for your own array? Let’s trace the journey from raw silicon to a power-pumping module built to thrive on Nova Scotia rooftops.

From Sand to Sunshine

Imagine picking up a handful of beach sand. Believe it or not, that plain sand is the first ingredient in every solar panel. Manufacturers heat and purify it until they get super-clean silicon, the magic material that turns light into electricity.

Step 1: Baking the Silicon “Cake”

Accordingly, factories melt that purified sand in giant ovens and pour it into thick blocks, a bit like baking a loaf of bread. When the block cools, it’s called an ingot.

Step 2: Slicing Ultra-Thin Wafers

Next, diamond-tipped wires slice the ingot into paper-thin wafers. Think of slicing cheese—only these wafers will soon capture sunshine.

Step 3: Adding the Electric “Secret Sauce”

Moreover, each wafer gets a tiny dash of special ingredients (boron or phosphorus). This step lets electrons start moving when sunlight hits—exactly what we need to create power.

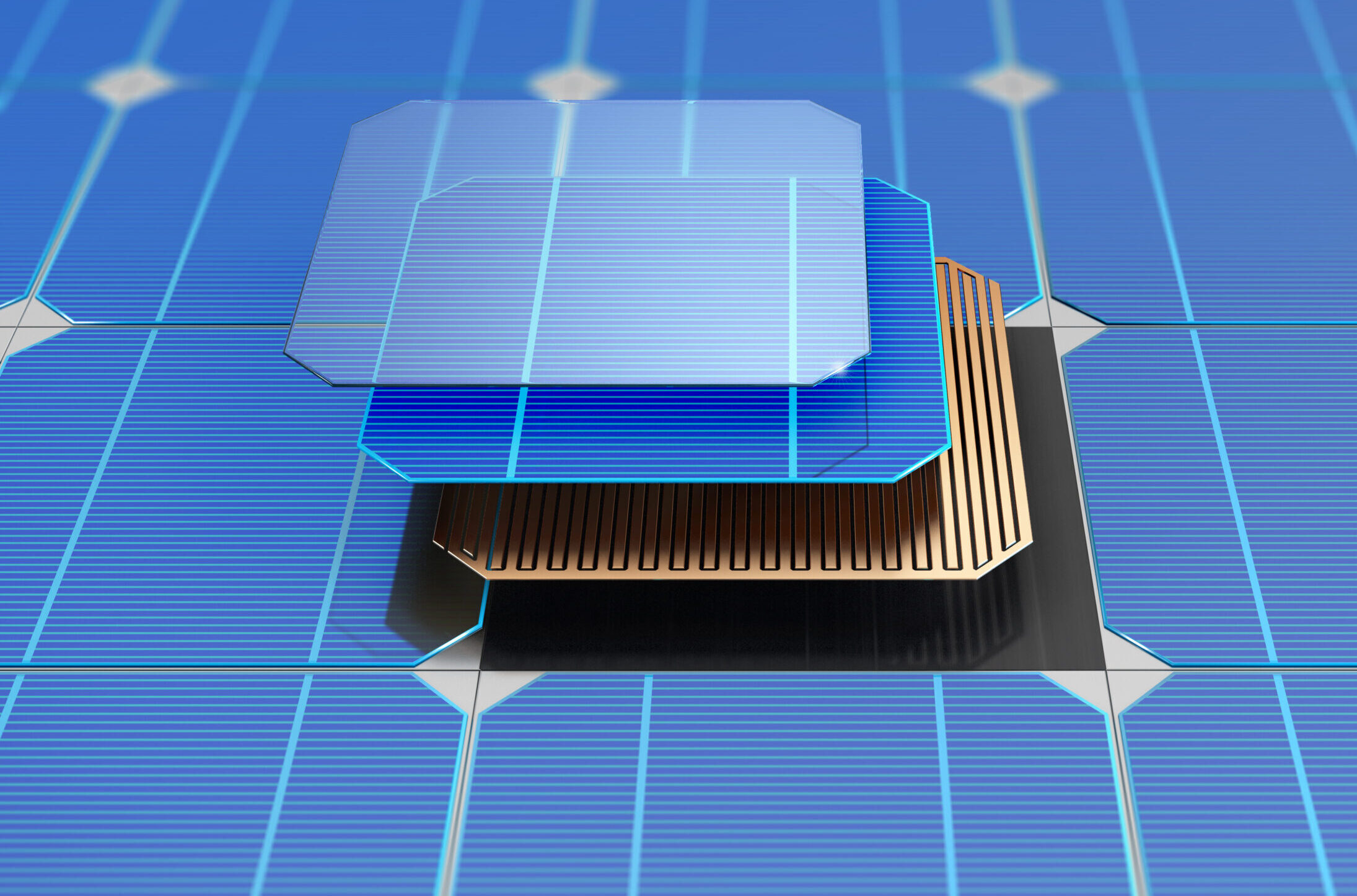

Step 4: Painting on Silver Pathways

Silver lines are printed on both sides of the wafer. These lines work like little highways, guiding the electrons out of the cell and into a circuit.

Step 5: Building the Protective Sandwich

Now, 60 cells line up side by side, wired together. They’re sealed between two clear plastic sheets, covered with strong tempered glass on top, and tough backing on the bottom—creating a weatherproof sandwich.

Step 6: Testing and Toughening Up

Each panel flashes under bright lamps that mimic the sun. If it reaches its promised power, it graduates. Panels like our go-to JA Solar JAM54D41-440/LB also face hail, heat, and cold tests, proof they’ll survive Nova Scotia blizzards.

Want proof? Check Energy.gov’s quick primer on how solar cells turn light into power.

Step 7: Journey to Your Roof

Finally, completed panels ship by boat, train, and truck to Atlantic Canada. An installer (hi, that’s us at Atlantic Solar) bolts them down, connects an inverter, and files the net-metering paperwork. Voilà—sun-powered savings.

Why This Matters for Nova Scotia

Consequently, knowing how panels are built explains why they last 25 + years and still crank out 80 % of day-one power. Strong glass, sturdy frames, and tight quality checks mean they handle 5 400 Pa snow loads and 225 km/h winds without flinching.

Keep Learning & Linking

Curious about toughness? Read Can Solar Panels Withstand Hail? Durability Facts. Wondering what happens decades later? See Proven Circular Solar Panel Recycling in Nova Scotia

In short, sand becomes silicon, silicon becomes cells, cells become a panel, and that panel becomes lower bills on your kitchen counter. Ready to tap into the process? Book a free assessment and let your roof join the sunny side of Nova Scotia.