Author: Mariela Guanchez

Ever stare at those gleaming panels and think, How exactly do they turn raw materials into a power-generating marvel?The journey is fascinating. Let’s take a closer look at how solar panels are made, from the refining of silicon through to the final assembly that ends up on your roof, providing renewable solar energy day after day.

Starting with Silicon

Nearly all modern panels rely on silicon, one of Earth’s most abundant elements. But it’s not as simple as scooping up sand. Manufacturers refine and purify silicon to a high grade, removing impurities that would hamper its ability to conduct electrons. The result is typically solar-grade silicon rods or ingots.

Ingot to Wafers

Those ingots get sliced into wafers—thin, shiny discs or squares that form the heart of a solar cell. Each wafer is then treated with chemicals to create the p-n junction that fosters the photovoltaic effect. Think of it like doping the silicon with tiny amounts of specific elements so electrons can flow when sunlight hits.

Cell Assembly

Once the wafer is primed, metallic contacts (often silver-based) are printed or etched onto the front and back. These channels guide the electrons out of the cell and into a circuit. After that, an anti-reflective coating is applied—hence the bluish or dark sheen panels sometimes have. This coating ensures more sunlight is absorbed, rather than reflected away.

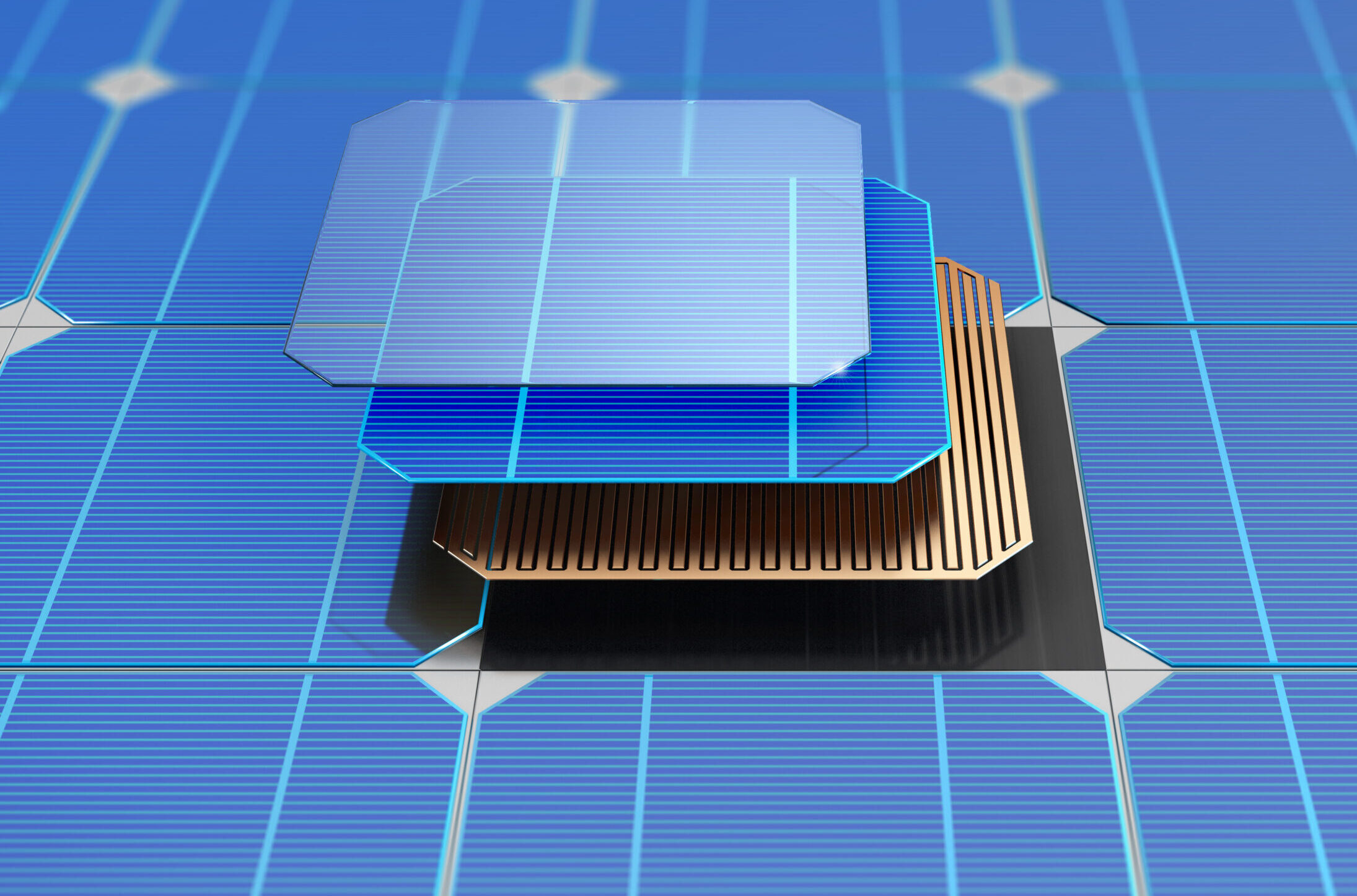

Creating the Module

Individual cells are wired together in series (and sometimes parallel) to form a solar panel or module. The entire sandwich typically includes:

- A tough backsheet for insulation.

- The interconnected solar cells in the middle.

- Encapsulation layers (often EVA or similar) that seal the cells and protect them from moisture.

- A top layer of tempered glass for durability and light transmission.

Quality Testing

Panels face rigorous checks: Are the cells all well-bonded? Can the panel withstand high temperatures, humidity, even hail? A flash test measures how much current and voltage the panel produces under simulated sunlight, verifying it meets its rated power. If it passes, it’s slapped with a label, framed in aluminum, and shipped to distributors worldwide.

Transport to Nova Scotia

From the factory, panels travel by ship, rail, or truck to local warehouses. Your installer sources them—potentially selecting certain brands known for reliability or efficiency. Atlantic Solar, for instance, carefully picks panels with robust warranties, proven track records, and certifications to handle Nova Scotia’s climate.

Installation & Beyond

Eventually, that refined slice of silicon and carefully layered materials end up on your roof, harnessing the sun. You witness the tail-end of a complex supply chain that started in a silicon refinery. Understanding how solar panels are made highlights the care behind every step—ensuring you get a reliable module that can churn out clean energy for decades.

Conclusion

From the raw element to final, glass-topped modules, solar panels are a testament to human engineering meeting Earth’s natural resources. Every time you watch your inverter’s production stats climb, you’re witnessing the fruit of that intricate process. Next time someone asks how those shiny panels on your roof came to be, you can share the short version of this incredible journey.